| Welcome, Guest |

You have to register before you can post on our site.

|

| Forum Statistics |

» Members: 53,715

» Latest member: Swig4646

» Forum threads: 68,133

» Forum posts: 1,054,786

Full Statistics

|

| Online Users |

There are currently 294 online users.

» 3 Member(s) | 289 Guest(s)

Bing, Google, avatar, Sean®, goaliedad

|

|

|

| Shelf on Coffee Table |

|

Posted by: Petertaylor - 09-18-2024, 08:35 AM - Forum: Woodworking

- Replies (3)

|

|

We are planning to build a coffee table with a shelf. What is a good way to attach the corners of the shelf to the legs? The table will be about 3x5 feet; the legs will be squarish, not round.

Thank for the help. —Peter

|

|

|

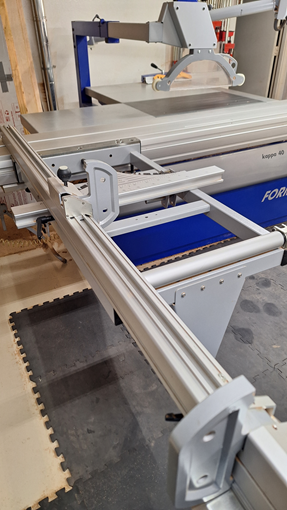

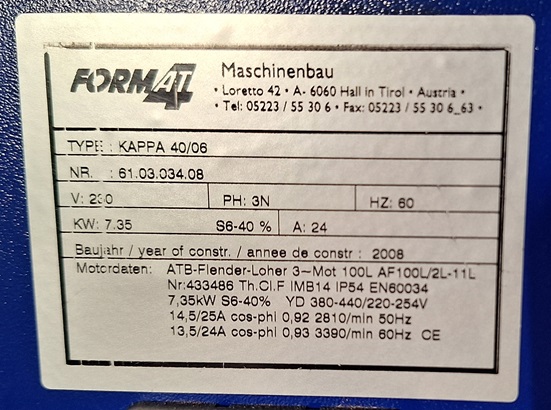

| Felder Format 4 Kappa 40 - 10 HP Sliding Table Saw |

|

Posted by: Shopdude - 09-17-2024, 08:15 PM - Forum: Tool Swap N' Sell

- Replies (2)

|

|

Gently used Format 4 Kappa 40 run only in a home shop environment.

10 HP 3 Phase motor with a 10 foot sliding table.

Electronics upgraded by Felder in 2018 including screen, controller, main board and voltage regulator.

Plugged in and available for demonstration in Punta Gorda FL.

$15,900.

Specifics from Felder invoice:

Circular Saw Kappa 40, 90-45 degree Sawblade 250-400mm, Max cutting height 133mm, electrical height adjustment

Flange set for Dados

X-motion Touch screen control 10.4”/264mm color display with touch function in the control panel at eye height, with A4 list holder for pieces; positioning control for height, angle and parallel cut; tool database for saw blades; cutting programs; grooves, row of grooves, rabbets and miter; USB interface and preparation for network connection; tiltable panel.

Electronic Display adjustment – inch.

Scoring unit with motor 3 X 230V, 1.1 kw 50/60 Hz for scoring blade D=120mm

Electrical height adjustment of scoring unit with automatic height setting on/offSpeed display for 3 speeds

Overhead saw guard for cutting width up to 1250mm, cover for 90 degree and for angle cuts adjustable in height, max. sawblade diameter 400 mm, cutting height 133 mm.

Sliding table, table length 3200 mm

Electrical switch station with scoring unit on sliding table

Miter index scale with length compensation

Position controlled motor driven rip fence Kappa 40 X-motion with digital display and cutting width 1250 mm

Electrical system 3X230V, 60 Hz, 7.35kW, soft start, 3 speeds, CE with brake

Operating manual included

Air clamp hoses, fittings and regulator included. Air clamps not included.

Blade change wrench included.

|

|

|

| Question about Garage Doors |

|

Posted by: doobes - 09-16-2024, 04:15 PM - Forum: Home Improvement

- Replies (8)

|

|

Greetings,

We had new house built last year which included an obscenely expensive garage door from a local door company.

I've already had to have them come out and look at the door (and make a bunch of changes to the installation) because it was creaking, groaning and popping.

Now some 5 months later, it's creaking, groaning and popping again.

I went and had a lookie see, and what is obvious that as the door travels on the tracks the wheels are extending outward.

With the door down, there is about 3/4" of shaft showing between the wheel and the bracket. With the door up, there is about 2" of shaft showing. This is a heavy door, and the shafts are angled downward from the load and the increased extension.

Just for laughs, I put my 4' Stanley level on the tracks attached to the wall:

As you can see here in 4' the track is about 1/2" off of vertical.

I've had garage doors for literally decades, and never had one that needed the attention this one has needed.

Are the uprights to your door vertical?

Thanks

|

|

|

| Wood sealant for greenhouse |

|

Posted by: brianwelch - 09-16-2024, 08:37 AM - Forum: Home Improvement

- Replies (4)

|

|

We are about to embark on the assembly of an 8 x 10 greenhouse purchased thru Costco...Wood components/kneewalls with polycarbonate glazing panels. All wood has been given a coat of water based stain/sealant at the factory and has been routed out (after staining/sealing) for the insertion of the glazing panels. I would like to give a coat or 2 of sealant prior to assembly, focusing on the grooves as they will not be accessible in the future and will most likely be subject to moist conditions, but also on all mating surfaces/joints. According to the manual the lumber used is Cunninghamia lanceolata.

Thoughts/suggestions on a good sealer product is appreciated...

TIA

|

|

|

| Length of turned legs |

|

Posted by: SmallTownUSA1 - 09-13-2024, 04:24 PM - Forum: Woodturning

- Replies (3)

|

|

Afternoon All,

I build furniture (mostly Shaker and Arts & Crafts style). I have a client that wants a Shaker style blanket chest. Plans call for four legs for the lower piece (the top piece fits into a lower piece).

I do not turn (although I build everything I do with hand tools only). As I mentioned, I need four turned legs. I can supply a turner with the profile of the leg. My question is:

If I need a turned leg that is 13" long, how much extra do I need to make the leg blanks so the turner can shape the legs on his/her lathe?

I have not yet located a person with a lathe or I could ask him/her the question.

Thanks,

Harold

|

|

|

| Maybe I should reconsider a segmented head |

|

Posted by: jteneyck - 09-13-2024, 02:14 PM - Forum: Woodworking Power Tools

- Replies (28)

|

|

for my jointer/planer, not the one on my shoulders. I took the blades out to sharpen today because there is a nick in them. Wow, I didn't realize how deep they were. It took me an hour to sharpen the three of them. That likely would have been a 10 minute job to rotate one or two cutters on a segmented head. I looked into one months/years ago, then let it drop because I'm cheap. Perhaps I should reconsider; I'd rather being cutting wood than maintaining equipment these days.

The issue isn't just the segmented head. Because of the increased power needed to run one, the anemic 3 KW motor likely will need to be replaced as well. I can barely take off 1/16" now w/o bogging it down, so I generally go 1/32" per pass. SLOW. With a segmented head it's going to be even less unless I put a new motor on it, so I think I'm looking at at least $2k. If the 750 lb thing weren't down in my basement shop it might make more sense to sell/replace it, but that's not going to happen at this point.

Anyone else dealt with this first world dilemma?

John

|

|

|

|