| Welcome, Guest |

You have to register before you can post on our site.

|

| Forum Statistics |

» Members: 53,715

» Latest member: Swig4646

» Forum threads: 68,136

» Forum posts: 1,054,860

Full Statistics

|

|

|

| Simple/cheap bench vise any good? |

|

Posted by: GaryMc - 09-08-2024, 12:40 PM - Forum: Woodworking

- Replies (3)

|

|

Kid next door is starting to get into woodworking, mostly small carved items so far. After seeing how he tried to clamp down objects, I volunteered to build him a small workbench, using a prefinished ash butcher block slab (22" X 28") for the top and legs/skirt/etc. from an old (100+ YO) barn timber. I am trying to help him with selecting a vise appropriate for his budget (very small) and talents (beginner). He has been crawling all over eBay but I saw nothing that didn't either look in poor condition or with a ridiculous price. I suggested he look at this $81 one from Amazon:

https://www.amazon.com/Yost-Woodworking-...0c00c&th=1

Looks to be a close knockoff of the Records which I have on my bench. Most of the negative reviews are from several years ago or are obviously from people who do not know how a bench vise is supposed to be mounted or how it works. My thought is to order it and if the form, fit, and function is not good, just return it (free).

Comments or other ideas, anyone?

|

|

|

| "we have a Plan" |

|

Posted by: bandit571 - 09-08-2024, 12:00 PM - Forum: Woodworking Hand Tools

- Replies (47)

|

|

According to Boris B.

"They may not work, but, I Always have Plan!"

So...

Moose & Squirrel Message Express Ltd dropped this off the other day...

As I need to make 4 of these "Doors"....for the Bathroom's Linen Closet...to replace these.."things"

4 doors....jambs for the hinges are worn out, doors are just framed up plywood panels..with several layers of white paint...that someone else tried to make into bi-fold doors..

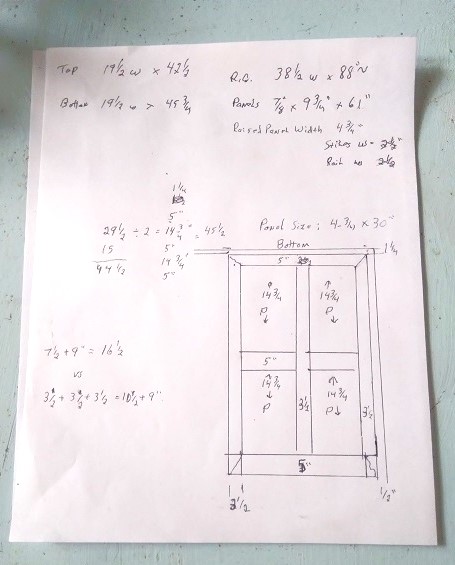

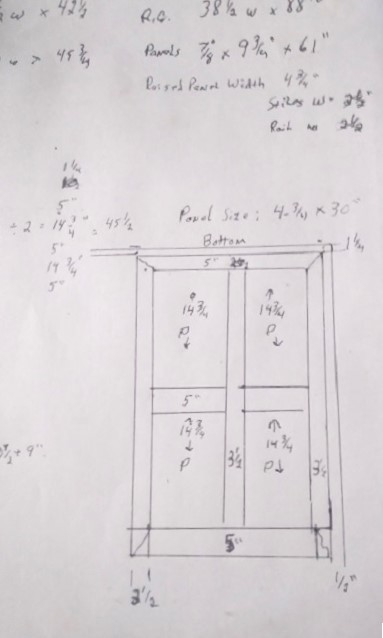

The Plan: Remember, this is just for ONE of the 4 doors...

Each to have 4 raised panels...I happen to have 2 planks, that were sawn from a 10' long board...@ 7/8 x 9-3/4" x 61" long....enough to make the 16 raised panels, and have the grain line up.

While sifting through the rest of the leftover Ash...decided I needed a Lumber Run...to get some decent looking planks to build the Frames from..so..

I can still use these for any short rails, but

Paid $8 for about 30' of 1 x 6 Ash....As I need to rip stiles from....would be 8 stiles @ 44" lengths, plus 4 center "stiles".

Need to haul the 1 x 10s to the shop, today...

And rip and crosscut into the 16 Raised Panels...so I can start cutting parts to build the frames around them...frames are to match up with the rest of the Doors details..

And carry those beads around all the raised panels, to boot.

Some be a fun 3 weeks of work? Stay tuned...

|

|

|

| Dewalt 735X planer?? |

|

Posted by: JTTHECLOCKMAN - 09-07-2024, 12:17 AM - Forum: Woodworking Power Tools

- Replies (14)

|

|

I am looking to upgrade my Delta 12" planer that is old and started giving me problems and I just about got every penny out of it. I want to buy the Dewalt735X planer which gets high marks and reviews as the best bench top planer on the market. Now they sell the same planer with a Shelix head instead of the straight blades but it is a $1000 more. But doing some homework I see you can buy the Byrd Shelix cutterhead separately and change it your self for about $600. The Planer is about $650 to $700 so the savings would be about $400. The thing is if you buy the OEM cutterhead you have to take all the cutters off and slide the head through the bearing raceways and then reinstall the cutters. Or you can buy a smaller version and only have to remove one or two rows of cutters to get through raceways. But in the end there is things that get thrown off because of the smaller diameter cutterhead. or I should say features like the depth gauge.

Now with this bit of knowledge that I have I would like to ask if anyone has the planer and with what cutterhead? If you changed to a shelix cutterhead did you get an OEM one or a smaller diameter? What was your experience changing heads? Are you seeing that much difference in cut quality? I am sure the carbide cutters would be smoother in all types of wood. I also understand that the Shelix head draws more amps during cutting than the straight blades so to begin with a 20 amp breaker is in need but with the universal motors on these you can only run for so long and it will overheat and cause the thermal button on the unit to trip or the breaker in panel. Have you seen this happen. I guess what I am asking is if you own one what are the opinions and the pros and cons? Thanks in advance.

|

|

|

| Used Sawstop bait and switch… |

|

Posted by: JDuke - 09-06-2024, 07:15 PM - Forum: Woodworking Power Tools

- Replies (4)

|

|

Saw a Sawstop cabinet saw on facebook marketplace with router table and lift attached for $2400. After some back and forth with the ‘seller” \

(Who turned out to be a proxy posting on facebook) they thought they had a buyer that fell through so they gave me the green light to come get it.

Hook up the trailer and drive an hour to the prize.

I get there, and they have the saw moved to the front of the shop. The saw is between the forks of a tractor where they have used the forks to lift the saw by the top and fence. Already starting off on the wrong foot, but hop out and get a closer look.

The router table has been pulled off and is away from the saw.

The proxy seller (guy who posted it) tells me the router table, lift, fence and router are NOT included even though they were clearly in the picture…

Actual seller does show up and tells me he is not including the router setup in the sale regardless of what was advertised.

Then try’s to sell me several other tools.

I left with nothing.

At least my 15 year old son got a couple hours of experience driving the truck with the 5x8 trailer in tow.

I missed a great gloat, but I already have a Sawstop and don’t really need another one, so not that great of a loss.

But if you see a bunch of woodworking equipment on facebook marketplace in east texas, be cautious and ask some questions before you make the drive…

Duke

|

|

|

| Question on width of paper for Jet 22-44 Osc |

|

Posted by: TBroussard - 09-06-2024, 10:44 AM - Forum: Woodworking Power Tools

- Replies (1)

|

|

I just picked up a first generation Jet 22-44 Oscillating drum sander at a school auction. I am in the process of changing out conveyor belt and general cleanup. It currently has 2 inch wide sand paper on it, but does it matter whether 2 inch or 3 inch is used? I was curious if spacing matters on the drum before I go and stock up.

Thanks in advance

|

|

|

|