| Welcome, Guest |

You have to register before you can post on our site.

|

| Forum Statistics |

» Members: 53,733

» Latest member: Ferdster

» Forum threads: 68,326

» Forum posts: 1,057,637

Full Statistics

|

|

|

| Shipping Furniture |

|

Posted by: Don_M - 04-14-2025, 10:49 PM - Forum: Woodworking

- Replies (20)

|

|

This is not strictly speaking a woodworking question and perhaps some of you that build furniture as a business might be able to help. I am building a small console for my daughter. She is in New York - I am in the SF bay area. Any thoughts on how to cost effectively ship a single piece of furniture? It is about 53”l x 24”h x 18”d. I recognize that your basic moving co. could handle but I suspect that would be quite expensive. Thanks

|

|

|

| diamond sharpening plate question |

|

Posted by: toolmiser - 04-14-2025, 04:18 PM - Forum: Woodworking

- Replies (8)

|

|

I recently purchased a diamond sharpening plate along with some "honing fluid". I apply a little fluid, sharpen tool, then what? Should I rinse off the plate (if so with what)? I watched some videos online but nobody that I saw addressed what to do after.

Thanks for your help.

|

|

|

| Large Inlays - not easy even with a CNC |

|

Posted by: jteneyck - 04-13-2025, 12:09 PM - Forum: Woodworking

- No Replies

|

|

I made some inlayed boards for a person where the inlay is fairly large. That brought up some problems that aren't an issue with small inlays. The large flat area under the bulk of the inlay will prevent the edges from seating properly if there's too much glue, but too little glue results in unbonded areas that sound hollow when tapped.

To make these, you create a male and a female part. The perimeters are cut with a V-bit; I used a 90 degree bit which gives edges at 45 degrees. Since my customer wanted the board to have the grain running at 25, I had to make a blank that had almost twice the area of the 12" square final board.

![[Image: AP1GczOHF9khVBT-oFQzxBlRN27JZQ15gtUlqoX0...authuser=1]](https://lh3.googleusercontent.com/pw/AP1GczOHF9khVBT-oFQzxBlRN27JZQ15gtUlqoX0owq2JgiKSUMwQQjjGGdWYIL-PNqIt-l20lqxYjPru4n5aIdXTrU5v1WrV8J8oH_IadTirdplk55EXWGvk-7iPGeAnCW9WNLDwxbNei5hJchNwaTgWVwbtw=w1443-h811-s-no?authuser=1)

![[Image: AP1GczPPpbOK4OUQgRcUvj5tUN4sbpuUW7ObyaLO...authuser=1]](https://lh3.googleusercontent.com/pw/AP1GczPPpbOK4OUQgRcUvj5tUN4sbpuUW7ObyaLOROof-JnCuf7W_kxTUyM36AcpSCnIFQv6uHxaCZog1qOWgZ1EMGbyNjeltDNAWWTFBTr-FBP7OVlhCpo3_vOlKqY5yPByfFwCl027AkzqCGacBlCEnASG1A=w1443-h811-s-no?authuser=1)

After the parts are glued together, and allowed to dry long enough that it doesn't warp when you remove the clamps, the extra part of the male piece is sliced or planed off and then machined flush with the background. If the board warps (much at all) it is very hard to do that w/o removing too much material in some areas. When that happens, gaps start to appear along the joints even though the two pieces should mate perfectly over their entire mating surface. There are lots of ways to fail at this, and I found a lot of them.

Anyway, these are what I ended up with. Not perfect, but pretty close. Two are cherry and maple, the other sapele and beech. Funny how the whale of the sapele/beech board looks larger than those from cherry/maple.

![[Image: AP1GczPBbt8NixMRzbWmZcTEcJEWy2_Lb7vXNLY3...authuser=1]](https://lh3.googleusercontent.com/pw/AP1GczPBbt8NixMRzbWmZcTEcJEWy2_Lb7vXNLY3NLHQ9VcrfTqtD1NB3HVqna6bAw5piDskmUemsyKpBDnptE4P8522kxCaEa_4-MKapduTFAl9TTYfukd2-ywUT3kmaRoYMP6K1jm6X5yDUxhce5EdWPiDhg=w485-h863-s-no?authuser=1)

John

|

|

|

| Lie-Nielsen Toolworks video by Portland, Maine TV show |

|

Posted by: shoottmx - 04-13-2025, 09:09 AM - Forum: Woodworking

- Replies (2)

|

|

This segment ran recently on the nightly news magazine show "207" where they often showcase a Maine small business. Reading through the comments it is evident a lot of folks are in love with their LN tools.

https://youtu.be/uBVdgMMPgZU?si=tQi9RClzrmnJNMox

My LN story: I have an early low angle jack that has been my go to for 15ish years. Some time ago I realized the sole wasn't flat so I drove up to Waldoboro (living in Maine has it's benefits) and spoke with one of the experts there. He offered to "square it up" if I could be without it for a few days, of course I agreed. A week or so later the plane was returned via UPS, sole ground flat and sides ground 90* to the sole. No charge. You just gotta love that company.

Gary

|

|

|

| Biesemeyer parts (out of business?) |

|

Posted by: jpohja - 04-13-2025, 08:52 AM - Forum: Woodworking Power Tools

- Replies (14)

|

|

Looking for a part for my Biesemeyer fence on my newer model Unisaw. Backordered in many places and roughly $30 for the "cam foot assembly" which is basically a small strip of metal so I don't understand the price unless maybe they are out of business and there is a short supply of parts.

A search of their location in Mesa, AZ indicates the business is "permanently closed"

Anyone know if they are out of business?

John

|

|

|

| Hinge install help |

|

Posted by: msweig - 04-12-2025, 11:52 AM - Forum: Woodworking

- Replies (6)

|

|

So I'm working on building a campaign style folding desk (specifically the one from Chris Schwarz's book). For anyone unaware of the basic design, imaging a basic table (four legs and aprons). The front two legs are attached to the front apron with typical M&T joints. Same with the back two legs and rear apron. The side aprons are actually four pieces (two on each side), with various hinges to allow the side aprons to fold in, which allows the base to collapse (making it easier for travel).

I'm having ...issues... with the hinges. Specifically with screws breaking when trying to install the hinges. Brass hinges with brass screws (both from Lee Valley, so quality should be good). I know brass is a bit more of a delicate metal, and I broke one screw when doing a test joint. So I decided to run to the hardware store and buy some wood screws from there (same thread pattern), figuring that I could drill the pilot hole, use one of these screws, then back it out and use the brass one as the final (figuring this would put less stress on the weaker screw). This has been a disaster. I've broken three of the screws (out of 6 for the first hinge). One of the three broke far enough down that I was effectively able to drill it out. The other two are stuck.

I think part of the problem is that I went with longer screws than called for (1.5" instead of 1"), figure this would hold better, and the screws end up being structural (two of the hinges are in end grain, including the first one I've been trying). The wood is soft maple, and I'm actually using larger than typically what one would use for a pilot hole. (I initially tried a smaller pilot hole (3/32), and when the first screw sheared I increased the size of the pilot hole. I'm up to 1/8" and still having this issue).

Any suggestions? I'm about at the point where this is going to just be a desk instead of a folding desk (I've got some extra lumbar left over and could just cut out two aprons and attach them to the side via dominoes). I could use that extra lumbar to remake the two aprons that have screws stuck in them so far, but that is an involved process and also includes roping in a friend to help (which I would prefer not to do). I'm also not sure how much my daughter cares about the folding feature (going to ask her later today).

But this still doesn't stop the problem I'm having of shearing screws off when installing hinges. I've had this happen before. Any suggestions? Better wood screw to use as the first/lead screw before using brass? (I'm sure the one I got from the hardware store isn't the best quality). What else? I'm driving the screws with a screwdriver and pausing every once in a while to allow heat to dissipate.

|

|

|

| Solar Post Lights |

|

Posted by: museumguy - 04-12-2025, 09:13 AM - Forum: Home Improvement

- No Replies

|

|

I need new solar post lights for my deck. I was never happy with the ones we bought when I built the deck and they are finally giving out on us. I need some that will fit a 4 x 4 PT post. Anybody have recommendations for good ones? How about ones to stay away from?

|

|

|

| FS: Woodworking Workbench -- Plus Router Table - Sun City, AZ - $500 |

|

Posted by: Paladin - 04-11-2025, 06:42 PM - Forum: Tool Swap N' Sell

- No Replies

|

|

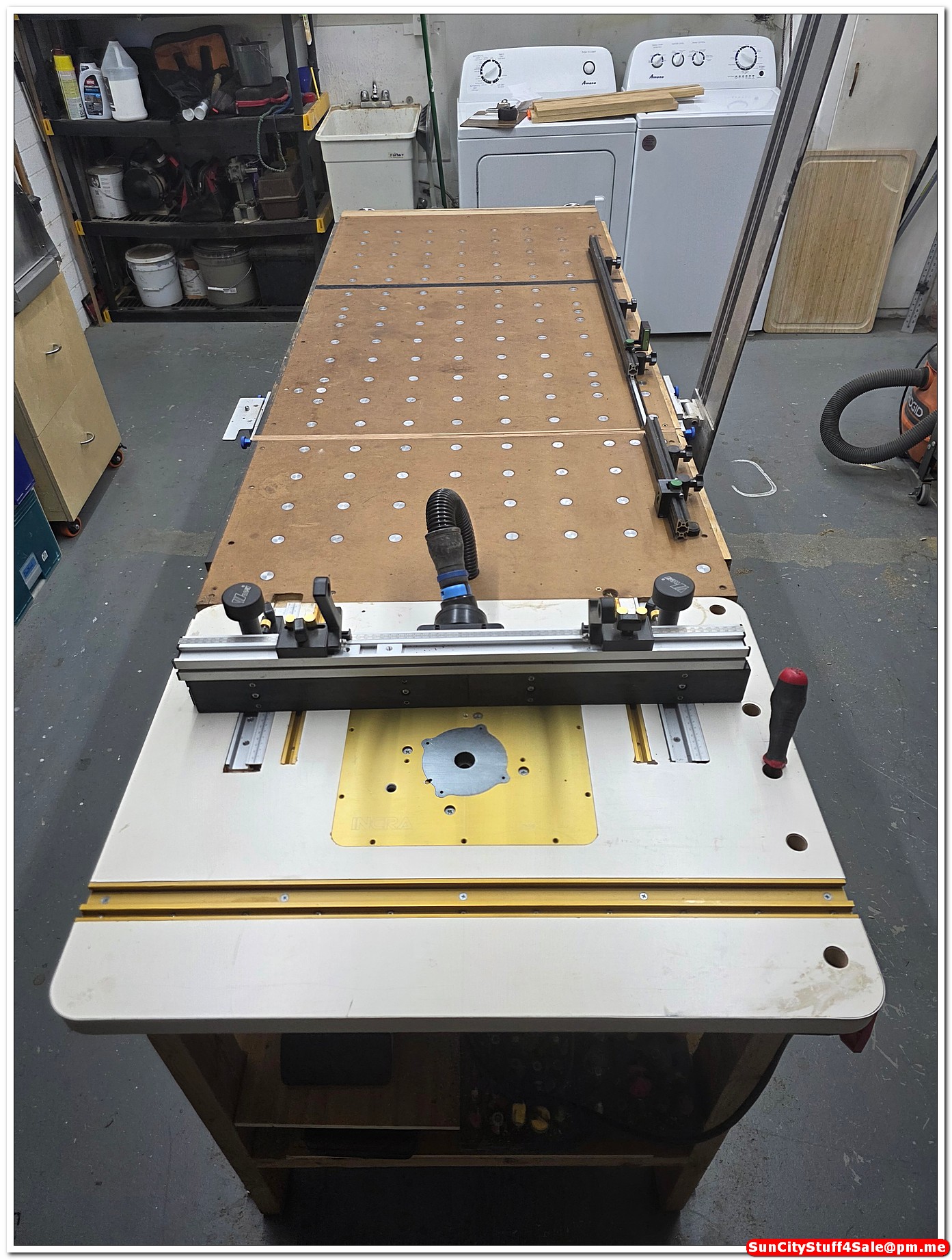

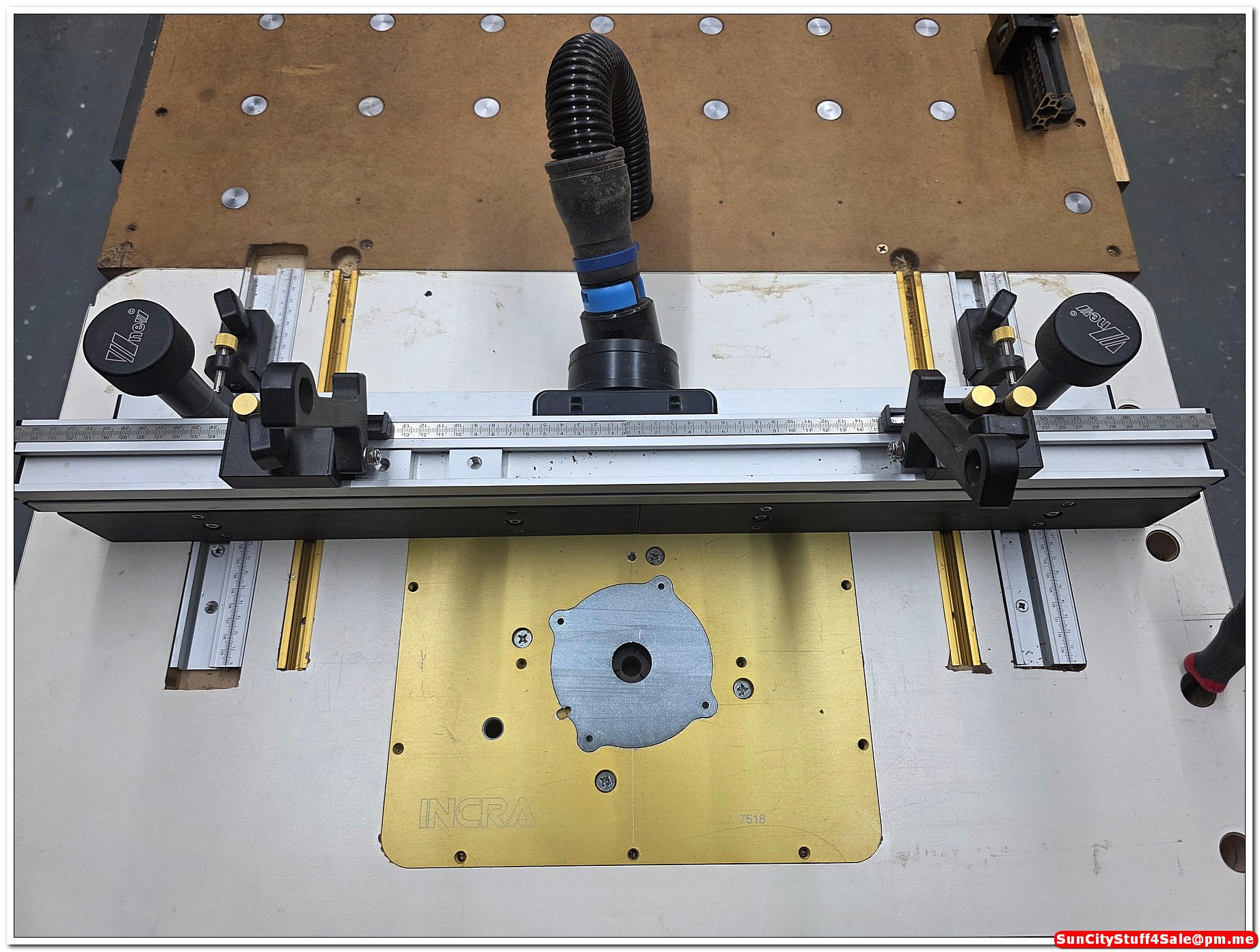

For sale, workbench and router table. I have the two tables attached to each other forming one big worktable. They can be separated. I am selling them separately, if you buy both, you have the whole package. If you only want one, that is fine.

ROUTER TABLE

The router table is 23 1/2” deep and 37 ½” wide. Currently $254 at Inca. This table is made by Incra and includes the MagnaLOCK™ Ring Inserts and MagnaLOCK™ Router Plate -- Currently $125 at Incra. The router is the famous Triton TRA001 3-1/4 HP Dual Mode Precision Plunge Router customized for router table use

(as opposed to handheld). Currently $380 on Amazon. The fence is ENJOYWOOD Wnew Woodworking Router Table Aluminum Profile Fence System 700mm with Sliding Brackets Bit Guard – currently available at $137. The total cost for the router table top, router plate, router, and fence is $901 and that does not include

tax and shipping. Plus, you get the stand to support everything. Asking price $500

WORKTABLE

The work table is 31½" wide and 76” long. It is 35¼" tall. It includes the vice you see on the end of the table and three drawers. The drawers can be opened from either side of the table. The dogs holes are 20mm on 96mm centers. This is the Festool MFT standard.

The fence you see if you look close is The Dual Fence System from Benchdog Tools. Delivers unparalleled accuracy and control for woodworkers who rely on precision. Designed with metric scale markings, these fence systems ensure that you can measure and align your

cuts with absolute precision. This is NOT included, but you can offer to buy it when you see the whole system. You can see more about it here ==> https://benchdogs.co.uk/collections/dual...ce-systems -- Asking price for the whole table is $500.

I see that a couple of pics of my Ridgid band saw with riser block and WoodSlicer blade is is the ad. I have not priced that machine yet, but I will if there is interest.

If the ad is “UP” it is available. All prices are OR BEST OFFER. We are moving to a smaller place and I do not have room for this stuff.

|

|

|

|