| Welcome, Guest |

You have to register before you can post on our site.

|

| Forum Statistics |

» Members: 53,733

» Latest member: Ferdster

» Forum threads: 68,332

» Forum posts: 1,057,740

Full Statistics

|

| Online Users |

There are currently 933 online users.

» 19 Member(s) | 912 Guest(s)

Bing, Google, brnhornt, ColinH, Rod Torgeson, EdL, tomsteve, trc65, ohtoolman, Roly, lincmercguy, WoodCzech, WriteRev, RobertW

|

|

|

| Odd-Jobs question |

|

Posted by: Tony Z - 07-03-2023, 10:22 AM - Forum: Woodworking Hand Tools

- Replies (12)

|

|

In my tool accumulation, I have several Stanley Odd-Jobs, including the Simpson Machine Company copy (made in Gettysburg, PA). My question, do any here actually use this tool? Stanley made it for around 30 to 40 years, discontinuing it in the 30's (IIRC), and common sense would say, if it was selling and/or being used, it would still be made.

So, do any here use this tool?

|

|

|

| Wood Body Smoother—Walnut? |

|

Posted by: phreddy - 07-02-2023, 06:29 PM - Forum: Woodworking Hand Tools

- Replies (6)

|

|

Hello all. I’m planning to make a wood bodied smooth plane using the Veritas plane hardware kit. I happen to have on hand a big chunk of walnut—big enough that I could easily saw out a billet in quartersawn orientation. I would laminate something hard wearing (probably bubinga) on for the sole. Does anyone have any experience using walnut for this application? Are there historical examples? Or is this just a bad idea and I should look for something harder or otherwise more suitable? Thanks.

Edit: this is the hardware kit. It uses a Norris style adjuster. Although there is a cross pin, I think it would be under less stress than a wedged blade.

https://www.leevalley.com/en-us/shop/too...e-hardware

|

|

|

| POM Table saw |

|

Posted by: DaveParkis - 07-02-2023, 09:03 AM - Forum: Woodworking Power Tools

- Replies (4)

|

|

Is anyone familiar with the POM brand of table saw? I found one with a slider, but I don't want it if it's crap. There are other tools there that are good quality, but I'm leary of the saw. Thanks!!

|

|

|

| 2 deep hollowing tools and 3 carbide tools |

|

Posted by: joezjr - 07-01-2023, 01:04 PM - Forum: Tool Swap N' Sell

- No Replies

|

|

1 streight----1 curved----3/4'' x 16'' tip to tip----$75 3 carbide tools---2 full size---1 small-----1 of the large is a negative rake scraper--$60 pickup magnolia,de 19962-----or pay shipping------pictures to be sent upon receiving your email address

|

|

|

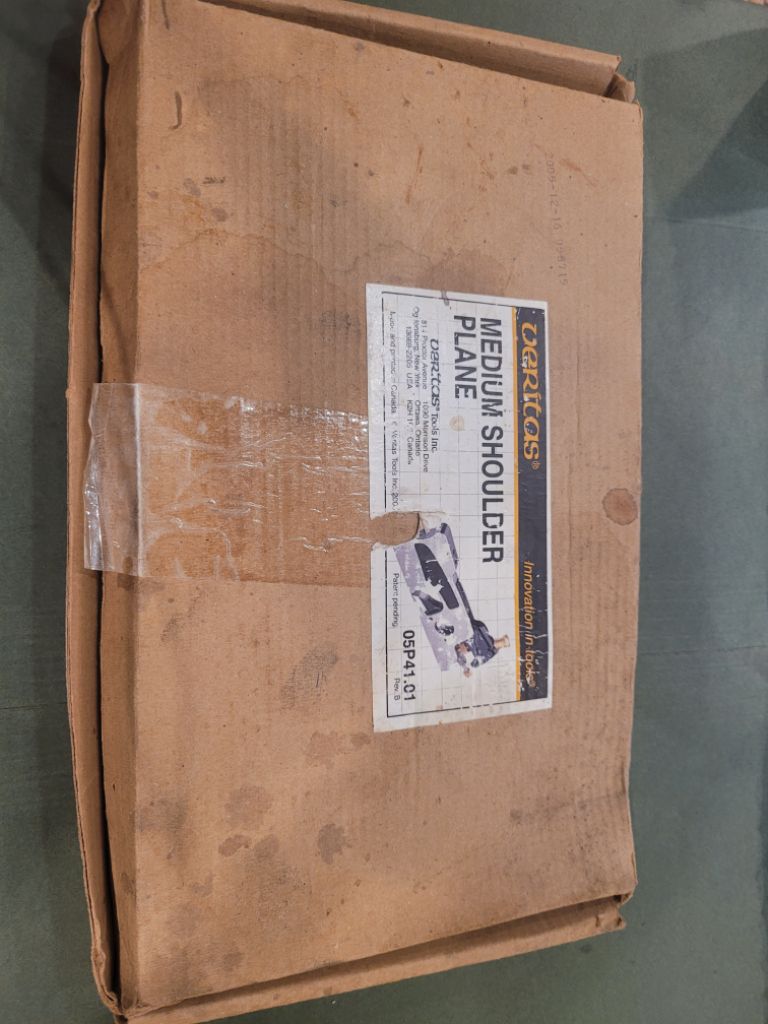

| SOLD: Veritas Medium Shoulder Plane |

|

Posted by: tocws2002 - 07-01-2023, 12:33 PM - Forum: Tool Swap N' Sell

- Replies (4)

|

|

I'm still frequently on this site, but it's been a while since I've posted and it's time to clear out a few items I don't use. Up for sale is a new Veritas Medium Shoulder Plane, including the original box. While this plane has not been used, it was subject to some moisture/water while still wrapped in the protective (oil-coated?) paper, so there was some surface rust and there is a little bit of pitting on the sides, but it doesn't affect the plane at all. The A2 blade is as new and has not been sharpened. All hardware and screws are in good condition and move freely. Attached are multiple pictures of the plane taken today, but if you need more or have any questions, please ask.

Asking $167.00 shipped (CONUS). Check, money order, PayPal accepted.

Thanks,

-jason

Cross Posted

SOLD

From the Lee Valley Website:

The Veritas medium shoulder plane is proportioned for versatility; it measures 7" long by 11/16" wide and weighs 2 lb. The ductile cast iron body is accurately machined and ground so that the sole and sides are flat and square.

If you have ever used or even held a traditional shoulder plane, you will appreciate how this plane comes to hand. The unique lever cap with a pivoting knob lets you adjust the plane to fit your hand and preferred holding style. The concave knob rests in the web of your hand, giving you a secure grip without the need of a vise-like pressure.

The through-hole in the body adds to grip security but has to be experienced to be understood. The plane’s adjustable toe lets you narrow the mouth for very fine shavings with minimum tear-out. The low bed angle of 15° combined with the 25° blade bevel results in a cutting angle of 40° for exceptional end-grain cutting performance. Set screws along the side let you accurately position the blade and require no adjustment when replacing the blade after sharpening.

Blades are lapped, 1/8" (0.125") thick, and come in A2, O1 or PM-V11 tool steel.

|

|

|

| Advice on finishing |

|

Posted by: GEB - 06-30-2023, 11:32 PM - Forum: Finishing

- Replies (2)

|

|

I have some Poplar (5’x 9”x 1½”) that will be a bar top in my BBQ shelter. I want to route in the names of the friends that helped me build the shelter. I am mobility challenged. What sequence of dyes, stains, and weather protection should I apply? I know Poplar does not stain well.

Bill

|

|

|

|