| Welcome, Guest |

You have to register before you can post on our site.

|

| Forum Statistics |

» Members: 53,731

» Latest member: jdhgmail2

» Forum threads: 68,311

» Forum posts: 1,057,471

Full Statistics

|

|

|

| Plywood cutter system? |

|

Posted by: DogwoodTales - 06-22-2025, 08:23 AM - Forum: Woodworking Power Tools

- Replies (9)

|

|

Years ago I attended a Kelly Mehler seminar and he showed us a blade system that had a plywood cutting blade with a much smaller blade leading the cut. The smaller blade would score the plywood face and the trailing larger blade would finish the cut.

I’m wondering what that tool is called and where I might find one. I don’t know exactly what to call it, so my internet searches on multiple search engines are bringing up results of anything but what I’m looking for.

Thanks

|

|

|

| Looking for mask recommendations |

|

Posted by: BrentDH - 06-21-2025, 04:23 PM - Forum: Finishing

- Replies (2)

|

|

What are you guys using for a mask when spraying solvent based finishes? I have an old cheap one that I think I bought at Menards many years ago when I was young and foolish and thought I would live forever. Now that I am older and more cautious I am noticing that I can still smell the finish when spraying which seems to me means that the mask is not completely doing it’s job? What would you recommend?

|

|

|

| Veritas stuff |

|

Posted by: DaveParkis - 06-21-2025, 10:05 AM - Forum: Tool Swap N' Sell

- Replies (2)

|

|

Hello everyone. Its been a while since I've posted. I tried to stop buying tools, I really, really did. Sadly, I get a ton of calls to liquidate tools and I can't always turn them away. So I am offering some nice Veritas Tools and a slick. I don't have PayPal anymore because someone hacked my account and wiped it out, so payment will have to be check or money order. Prices do not include shipping. First unconditional "I'll take it" gets it.

Veritas holdfasts.................$150 for the pair

Grinder Tool Rest..................$40

MK II honing guide (old style)......$60

Inset Vise, unopened.............$75

Variable Angle Plane Fence, unopened.....$50

Apron plane w/leather holster.........$80

Small Scraper Plane.......$90

L.&I.J. White slick, 3".......$150

I can't figure out how to post pics, if there's something you're interested in, please PM me with an email address and I'll send pics. Thanks for looking!!

|

|

|

| A few more finished saws, (of course) |

|

Posted by: RonB1957 - 06-19-2025, 09:28 PM - Forum: Woodworking Hand Tools

- Replies (3)

|

|

12" x 3" x 0.020" mahogany carcass saw. 13 ppi x 15* R x 25* fleam.

![[Image: 54600337172_6be66f132b_z.jpg]](https://live.staticflickr.com/65535/54600337172_6be66f132b_z.jpg) Cuban Mahogany 12" x 3" x 0.020 carcass saw by Ron Bontz, on Flickr" /> Cuban Mahogany 12" x 3" x 0.020 carcass saw by Ron Bontz, on Flickr" />

![[Image: 54601521655_47c4820a4f_z.jpg]](https://live.staticflickr.com/65535/54601521655_47c4820a4f_z.jpg) 20250619_130820 by Ron Bontz, on Flickr" /> 20250619_130820 by Ron Bontz, on Flickr" />

![[Image: 54601521595_57d61dcd38_z.jpg]](https://live.staticflickr.com/65535/54601521595_57d61dcd38_z.jpg) 20250619_130830 by Ron Bontz, on Flickr" /> 20250619_130830 by Ron Bontz, on Flickr" />

14" x 3" x 0.020" Walnut Carcass saw 14ppi x 15*R x 25* fleam

![[Image: 54601521400_12e6e2710f_z.jpg]](https://live.staticflickr.com/65535/54601521400_12e6e2710f_z.jpg) 14" x 3" x 0.020" walnut carcass by Ron Bontz, on Flickr" /> 14" x 3" x 0.020" walnut carcass by Ron Bontz, on Flickr" />

![[Image: 54601216221_659ba50a57_z.jpg]](https://live.staticflickr.com/65535/54601216221_659ba50a57_z.jpg) 20250619_131332 by Ron Bontz, on Flickr" /> 20250619_131332 by Ron Bontz, on Flickr" />

![[Image: 54601427563_6465d655b9_z.jpg]](https://live.staticflickr.com/65535/54601427563_6465d655b9_z.jpg) 20250619_131338 by Ron Bontz, on Flickr" /> 20250619_131338 by Ron Bontz, on Flickr" />

Basic 12" x 2" x 0.020" Apple dovetail 15ppi x 6* rake x 0* fleam

![[Image: 54600337027_c84f63f8a3_z.jpg]](https://live.staticflickr.com/65535/54600337027_c84f63f8a3_z.jpg) 12" x 2" Apple dovetail 38* hang by Ron Bontz, on Flickr" /> 12" x 2" Apple dovetail 38* hang by Ron Bontz, on Flickr" />

![[Image: 54601216396_43fdc5d9da_z.jpg]](https://live.staticflickr.com/65535/54601216396_43fdc5d9da_z.jpg) 20250619_131110 by Ron Bontz, on Flickr" /> 20250619_131110 by Ron Bontz, on Flickr" />

![[Image: 54601216376_f43bf8a034_z.jpg]](https://live.staticflickr.com/65535/54601216376_f43bf8a034_z.jpg) 20250619_131118 by Ron Bontz, on Flickr" /> 20250619_131118 by Ron Bontz, on Flickr" />

Well, that's all she wrote except for a couple of bog oak saws in the works. Still need to make the triple loop spines for those.Then it's on to a couple of cabinets and honey dos for a few months.

|

|

|

| Thoughts on dual fuel HVAC system |

|

Posted by: FrankAtl - 06-19-2025, 07:41 AM - Forum: Home Improvement

- Replies (7)

|

|

On our property we have a main house and a guest house. The guest house is two stories with my woodworking shop on the first floor and a one bedroom, garage apartment on the second floor that I use for my office since I work from home. The HVAC system has a gas furnace that still works but the air conditioner just can't keep up any longer. The system is 27 years old so I would say I got my money's worth out of it!

I've had a couple different HVAC companies quote a replacement and the guy that came out yesterday quoted a standard gas furnace but also quoted an option for a dual fuel system. This type of system uses a heat pump for primary heating but will switch over to the gas furnace when the temp drops below the threshold where the heat pump becomes inefficient. I'm considering this option because it would require much less propane (wouldn't have to fill the tank as often) and I would think heating primarily with electricity and occasionally with gas would be cheaper than heating 100% with gas.

The average winter temperature in this area is 38-58 degrees but it can drop down in the 20's and teens sometimes. Anyone here have experience with this type of system and if so, what are your thoughts?

TIA!

|

|

|

| Where is Timberwolf? |

|

Posted by: rfeeser - 06-18-2025, 09:45 PM - Forum: Woodworking

- Replies (6)

|

|

Has anyone seen a posting by timberwolf recently? Jack would be around 95 now, and I am afraid he has passed away. If so, I will miss him greatly.

I was a very active member of woodnet for a few years starting around 2005. I got to know Timberwolf then though his thoughtful postings. After a long lapse from woodnet, I started checking woodnet a few times again just a 2 - 3 years ago. I saw he was still active on the forum. So I started a regular correspondence with him, exchanging private messages every few weeks. He was 93 at the time, and we discussed the problems of aging a lot. I had some problems a bit over a year ago and stopped corresponding with him for a while. Now, when I tried to resume the correspondence, I have gotten no response from him. I also have not seen any postings from him, though I may just have missed then. I'm hoping someone has knowledge of him.

Jack lived in St. Petersburg, FL. Anyone there know him?

|

|

|

| Festool Domino DF500 (Sold) |

|

Posted by: fredhargis - 06-17-2025, 03:43 PM - Forum: Tool Swap N' Sell

- Replies (1)

|

|

I'm selling my Domino. Allow me to explain first. Last Sunday our kids/grandkids gave me a new one, the Anniversary version. After they left i explained to my wife I wanted them to return it and get their money back. That led to a long discussion about me disappointing the kids who worked long and hard figuring what to get, and they all chipped in to buy it, and on and on. You get the picture? Anyway, so now I'm selling my old one. The price is $500 + shipping, and i can take PP F&F, or a check in the mail. I'll leave this here for a week, then off the FB for $600. So here we go:

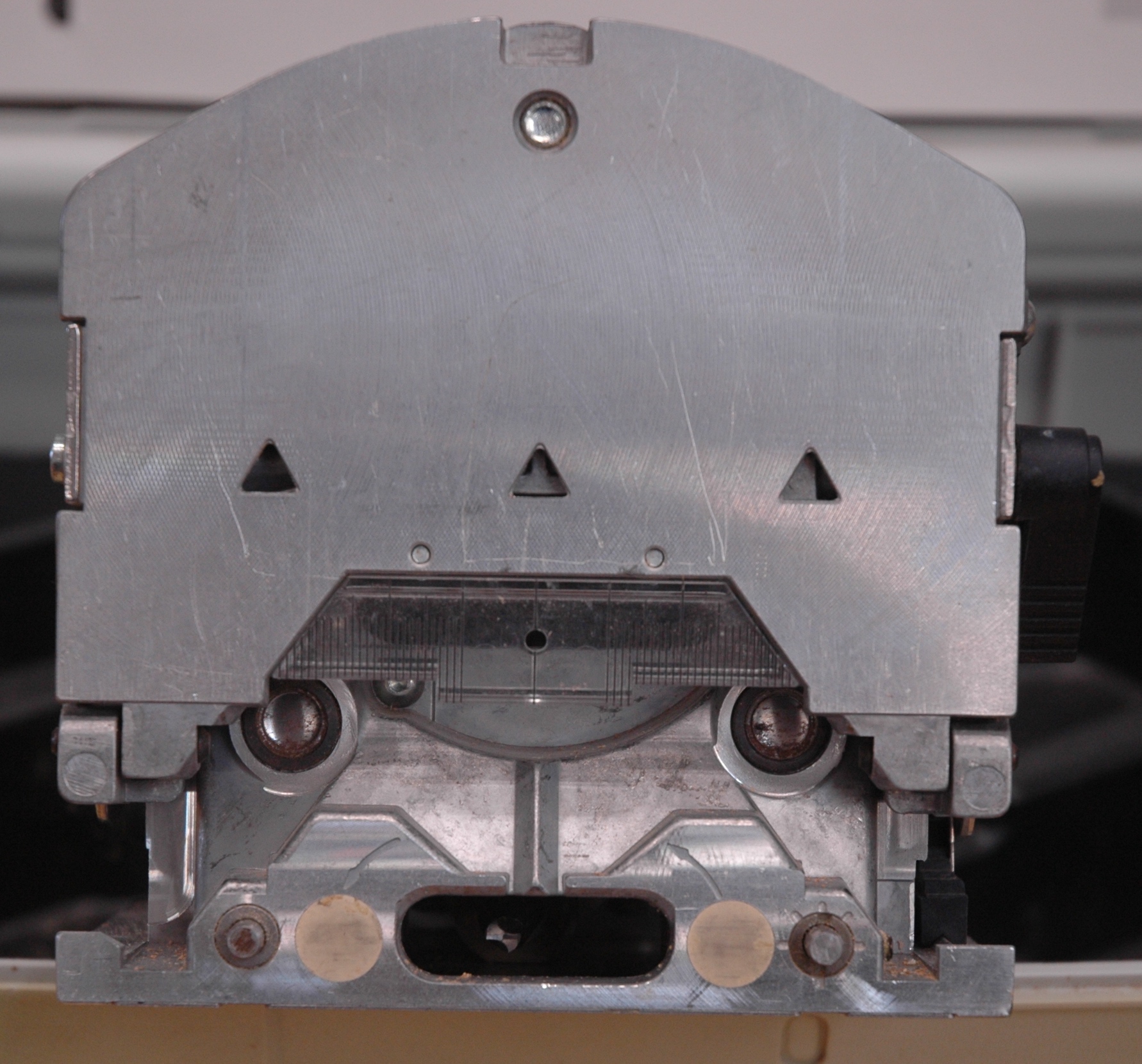

This a Domino DF500. It is an older model, made in 2007. Note that this has the pins for cross stops instead of the stop dogs put on the more recent models. Otherwise this is the same machine. This one is in excellent working condition, the only modification I made was to wrap some duct tape around the vac port so my vac hose would fit right on it. It comes with the 5mm bit, the base support bracket, the narrow frame fence and the outrigger guides. not included is the owner manual, though they are readily available on line. I’ll also throw in a small bag of 5mm tenons so you can try it out right away. After market bits (and tenons) are available in 4mm, 6mm, 8mm, and 10mm sizes. You can see the systainer has some color fade and is the older 2 latch type as well. The date of manufacturer is shown in the pics, as well as the duct tape I wrapped around the vac port. You can also see the machine is in very good condition and has not been mistreated at all. My price is well below 1/2 the price of a new one. Here's the pics:

|

|

|

|