| Welcome, Guest |

You have to register before you can post on our site.

|

|

|

| My Sharpening Bench |

|

Posted by: bandit571 - 07-31-2025, 08:21 AM - Forum: Woodworking Hand Tools

- Replies (8)

|

|

Nothing fancy...

What you see, is what I got...

On the Kitchen Counter top...right next to the Kitchen Sink...

I start with 2 clean rags..one to keep the counter clean...the other to keep the irons clean...

Seems a few planes were in need of a decent sharpening...so..

First up...

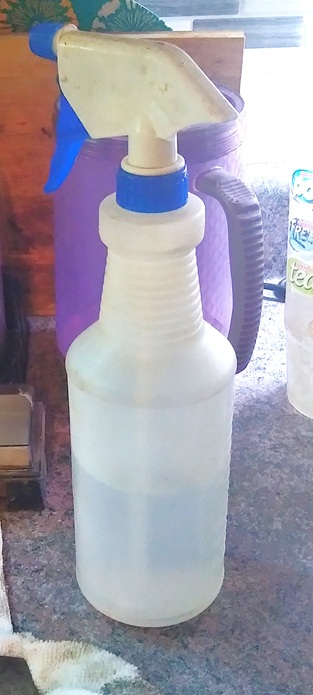

A 280 grit water stone..working on both the bevel and the back...twice..clean off after each...helps to keep a water bottle handy, too..

Rub the stone with the flattening stone..couple of spritz and away you go...

Next up?

1000 grit...was showing a lot of striations from the edge of the bevel...left behind by the 280? work both bevel & back,,,clean things off..

Next..

1500 grit stone...again working both faces, twice...Last pass was on the back..

And then, finally...

Finish up with the 6000 grit....

I also made sure that the chipbreaker sit gap free...and is set back about 1mm once the two items are bolted back together...

Install back into the Stanley No. 6c, Type 17..and take it for a test drive on some Soft Maple..

Bring the plane and the shaving back upstairs ( where the tripod mounted camera was)

Calipers said the shaving was around 0.002" thick?

Should be good enough for a Small Jointer Plane...

YMMV, of course...but this is what I use...

Have had to use a grinder on a few irons...mainly a 3 minute trip to flatten the back...I use a free-hand approach, no guides needed..just a pair of old hands.

Just another Sharpening Thread? We'll see...

|

|

|

| 3-Stage Water Filtration Systems |

|

Posted by: doobes - 07-29-2025, 12:51 PM - Forum: Home Improvement

- Replies (13)

|

|

So,

When we built the house, I bought one of these and had it installed as part of a water distro system to the sink and refrigerator,:

LOML and I were headed out on Friday to our daughter's house in Raleigh, when my wife commented on the wet floor in the garage.

As it turns out, it was the filter, so I just shut off the inlet valve and we departed.

Looking at it last night after we got back, it looked like the push in tube fitting was leaking, so I went and bought new brass compression fittings to replace the plastic push ins.

Trouble is, it wasn't the fitting.

Taking the thing off the wall, the tops of all three housings are split where the fittings are threaded.

So, I go looking over at the 'zon, and virtually everyone one of these 3 filter systems has a goodly number of people complaining about leakage due to split housings.

So, I'm throwing this out there for ideas on alternatives that I won't be replacing every 2 years.

Thanks in advance

|

|

|

| Making a B-17 serving tray |

|

Posted by: mtrainer90 - 07-29-2025, 09:42 AM - Forum: Woodworking

- Replies (4)

|

|

Making a custom Boeing B-17 serving tray for a good pilot friend. The Red Oak tray features a B-17 with the inscription "hell from heaven" and "398th Bomb Group- Heavy, 601st Squadron" which is where my friends grandfather served as a lead navigator. After everything was cut out on the FoxAlien 4040 XE-PRO, it was filled with Alumilite clear cast resin. The tray was sanded to 1000 grit and 3 coats of Waterlox Gloss was applied before wet sanding and a final coat.

|

|

|

| Door Lock Smart Lock for front door |

|

Posted by: Marilynchildress - 07-25-2025, 11:38 AM - Forum: Home Improvement

- Replies (3)

|

|

Hello Friends,

I hope you are all fairing well.

I have an Oaks Lock on the door for our Air BnB and have ordered 2 different gateways for it and neither work. I’ve ordered yet another gateway, because 2 people said that it hooks up easily with their Oaks…so we’ll see.

I’m wondering if someone might share with me what smart door lock for home they use remotely? We travel quite a bit and it would be helpful to set a new code for the door while I am out of town. Currently I need to be within 6 feet of the lock to set a new code.

Any info would be greatly appreciated.

Thanks,

|

|

|

|